Trench drain systems serve as the backbone of effective surface water management, vital for safeguarding infrastructure and maintaining safe, functional environments in both public and private settings. These highly engineered drainage solutions are specifically designed to intercept, direct, and remove surface water before it becomes a hazard, thereby reducing the likelihood of flooding and water-related structural damage. From expansive airport runways and industrial factory floors to community recreation parks and residential driveways, trench drains provide a robust answer to challenges posed by water runoff, soil erosion, and debris accumulation. By channeling excess water away, trench drains protect not only the longevity of built structures but also public safety. For organizations searching for reliable and expertly crafted trench drainage solutions, Cruco Mill & Industrial Supply remains a leader in the field, offering a comprehensive range of trench drain components, technical support, and tailored advice to meet specific project needs.

The urgency to implement high-performance trench drain systems has never been greater. Accelerated urban development, coupled with increasingly unpredictable weather brought on by climate change, poses continuous threats to property and infrastructure through frequent heavy rain events and flash flooding. Selecting the right trench drain system is not simply a matter of compliance but a proactive measure to protect people, property, and the environment. Property managers and owners can make well-informed choices by deepening their understanding of trench drain types, the latest materials, emerging installation techniques, and ongoing maintenance. This approach ensures effective stormwater management and infrastructure resilience in a rapidly changing world.

Table of Contents

What Are Trench Drain Systems?

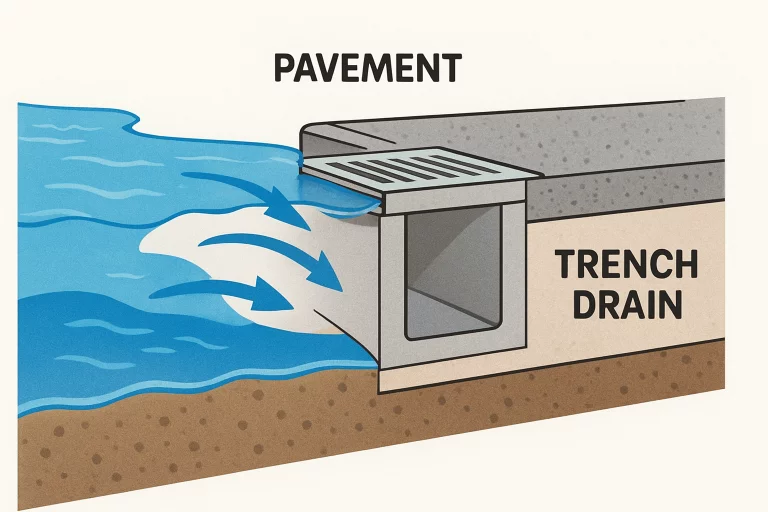

A trench drain system, also commonly known as a channel drain or linear drain, is an elongated, narrow channel designed to capture and convey surface water, liquids, or even hazardous materials efficiently. Installed flush with the ground surface, trench drains are characterized by a length significantly greater than their width, with channels ranging anywhere from just 1 inch up to 2 feet wide and depths extending to 4 feet in heavy-duty applications. The primary function of a trench drain is to collect water at the surface level and expediently direct it toward an appropriate outflow or containment area, preventing puddling, soil erosion, and the myriad forms of water damage that can threaten infrastructure and surrounding landscapes. Modern trench drain systems can also double as protective conduits for utility lines or as safeguards to contain accidental chemical spills within industrial complexes.

The efficiency, adaptability, and robust construction of trench drains underpin their widespread adoption across demanding environments. Their linear design allows for maximum interception of surface flow, making them invaluable on sloped surfaces, around large open areas, and in locales where rapid water removal is crucial. Thanks to tailored engineering and material advances, trench drains meet a wide spectrum of capacity and load requirements, serving everything from highways and transit terminals to backyard patios.

Key Applications of Trench Drain Systems

The adaptability of trench drain systems allows them to perform in an impressive array of settings, combating surface water accumulation and guarding against environmental hazards. Typically, these systems are engineered to quickly manage high volumes of water and respond to emergency spill containment situations. Common and critical applications include the following:

- Airports: The safety and operability of runways, taxiways, and aprons heavily rely on fast and effective water removal. Trench drains minimize hydroplaning hazards for airplanes, support timely takeoffs and landings, and help keep airport operations running smoothly, even during peak rainfall or snowmelt periods.

- Industrial Facilities: Factories, warehouses, and chemical plants demand trench drains to remove surface water and manage process fluids and accidental chemical spills. An effective trench drainage system lowers accident rates, maintains indoor air quality, and drastically reduces environmental contamination risks.

- Urban Areas: Urban planners and municipal authorities utilize trench drains along roadways, between curbs, and in public plazas to reduce flooding, mitigate slip hazards, and ensure pedestrian and vehicular zones remain accessible and safe, regardless of weather conditions.

- Residential Properties: Homeowners benefit from integrating trench drains in driveways, around patios, pool decks, and landscaping edges. These drains manage stormwater runoff, prevent basement flooding and erosion, and minimize costly repairs to foundations and gardens.

From heavy industrial demands to everyday residential applications, trench drain systems’ flexibility and customizability make them the drainage solution of choice wherever water control, safety, and property protection are paramount.

Materials Used in Trench Drain Systems

The performance and durability of a trench drain system rest on selecting the proper materials, choices influenced by budget, site conditions, anticipated traffic loads, chemical exposure, and aesthetic requirements. Today’s trench drain materials are engineered to strike the right balance between longevity, resilience, and environmental impact:

- Concrete: Standard concrete trench drains are well-known for their exceptional strength and affordability. Their robust configuration makes them ideal for heavy-duty locations like airports, shipping docks, and industrial yards. Nonetheless, they may require steel reinforcement, careful curing, and periodic monitoring for cracking or spalling under freeze-thaw or chemical attack conditions.

- Polymer Concrete: Increasingly preferred in specialized environments, polymer concrete is a mixture of aggregate and polymer resin, conferring superior chemical resistance, smoothness, and abrasion tolerance. It is a popular choice for commercial kitchens or laboratories where exposure to harsh cleaning agents or chemicals is frequent.

- High-Density Polyethylene (HDPE): HDPE trench drains are prized for their lightweight, flexibility, and resounding corrosion resistance. These attributes make HDPE suitable for settings where speedy installation, cost control, or resistance to caustic substances is vital, such as in green infrastructure initiatives and remote job sites.

- Stainless Steel: Stainless steel’s non-porous, corrosion-resistant nature makes it indispensable in environments where hygiene is a top priority, including food and beverage plants, medical facilities, and pharmaceutical plants. Stainless steel trench drains are durable and effortlessly withstand mechanical impact and aggressive cleaning regimens.

Selecting the appropriate trench drain material tailored for the application and environmental demands directly influences system longevity, reduces lifetime maintenance costs, and supports sustainability.

Installation and Maintenance Considerations

Trench drain systems must be installed with precision and maintained consistently to achieve peak performance and prevent premature failure. Adhering to industry best practices keeps drains flowing freely and maximizes efficiency and lifespan.

Site Assessment: The process begins with a meticulous evaluation of the terrain, runoff volume and velocity, soil composition, and required traffic load. This assessment guides engineers and contractors in choosing the correct trench drain style, load class, and location for maximum effectiveness.

Correct Slope: Each trench drain system must be set with the right slope or gradient to encourage gravity-assisted water flow. Proper slope designs not only curtail stagnation but also promote self-cleaning, reducing the incidence of debris buildup inside the channel.

Regular Cleaning: Periodic removal of leaves, sediment, and trash is mandatory. Clogged trench drains can quickly result in overflows, pavement damage, or even infrastructure failure, so maintaining an inspection and cleaning schedule is crucial, especially before rainy seasons.

Inspection: Scheduled checks for signs of wear, physical damage, displaced grates, or chemical corrosion help detect problems early. Timely preventive repairs and part replacements stymie small issues before they translate into large-scale water management failures and major expenditures.

Investing in trench drain installation and diligent maintenance pays long-term dividends by guarding critical infrastructure, cutting recurring repair costs, and promoting year-round water safety.

Emerging Trends in Trench Drain Technology

The trench drain industry continues to experience a wave of innovation, driven by growing environmental awareness and a drive for smarter, more efficient infrastructure. Key trends shaping the future of trench drain technology include:

- Smart Drainage Systems: The integration of IoT-enabled sensors into trench drain channels and grates now enables real-time monitoring of water flow rates, sediment accumulation, and potential obstructions. Such systems provide instant alerts, allow for proactive maintenance, and help facility managers avoid costly shutdowns or emergency repairs by addressing blockages before they escalate.

- Eco-Friendly Materials: Responding to regulatory pushes and consumer demand, manufacturers are increasingly embracing recycled plastics and sustainable composites in trench drain production. These environmentally conscious options help reduce waste, lower carbon footprints, and support projects aiming for green certifications.

- Modular Designs: Today’s modular trench drain systems feature snap-together components, simplified jointing, and tool-free installation. This reduces on-site labor and allows for easier system expansion, rapid upgrades, and straightforward repairs—perfect for evolving sites and phased developments.

These progressive trends are redefining the standards for drainage solutions, paving the way for greener, smarter, and more resilient infrastructure capable of facing extreme weather, urban growth, and environmental challenges.

For a more in-depth technical exploration, definitions, and internationally recognized standards pertaining to trench drains, refer to the comprehensive Wikipedia page on trench drains. Whether preparing for a new construction project or enhancing an existing drainage system, embracing innovative strategies and partnering with reputable suppliers is fundamental for ensuring high performance, longevity, and regulatory compliance in all applications.