Table of Contents

Understanding DOT Inspections

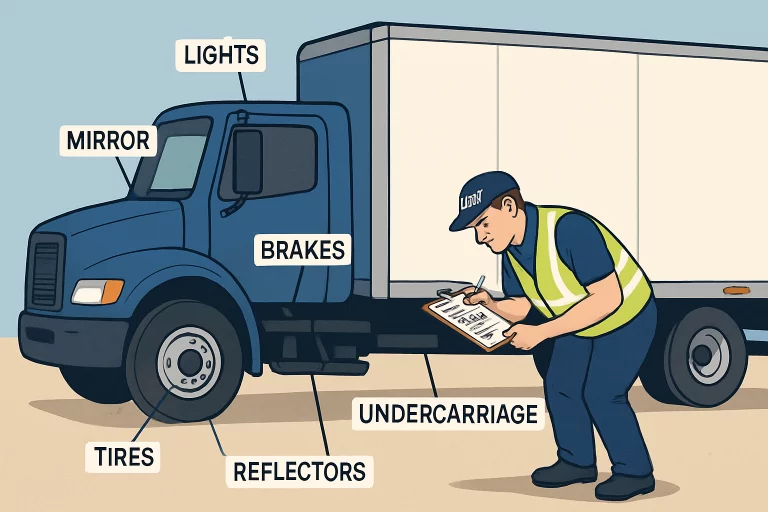

Routine inspections are key to ensuring commercial vehicles remain safe and compliant. These checks cover various aspects, including brakes, lights, tires, and driver documentation, all aimed at reducing the risk of accidents and mechanical failures. Operators are responsible for keeping their vehicles in top condition and adhering to established safety standards. Regular reviews, like those required under DOT inspections Minnesota, help identify issues before they become serious hazards. These inspections are structured to promote accountability and consistency across the industry, benefiting drivers and the public. Staying proactive with maintenance and being familiar with inspection criteria can prevent delays, fines, and potential liability. Ultimately, these inspections are a preventive tool supporting operational efficiency and public safety.

Key Components of a DOT Inspection

Successfully passing a DOT inspection requires attention to multiple critical vehicle components. Inspectors want complete confidence that each aspect of the vehicle is functioning correctly and presents no risk to road safety. Some of the essential elements include:

- Brake Systems: Regular brake checks are essential since poor maintenance can lead to accidents. Inspectors assess pad thickness, drum and rotor condition, air lines, leaks, and overall system responsiveness.

- Tires and Wheels: Tires must meet tread depth requirements, be free from damage, and be properly inflated. Inspectors also ensure that tire types match and wheel assemblies are secure and undamaged.

- Lights and Electrical Systems: Vehicles need fully operational headlights, brake lights, turn signals, and reflectors. Electrical wiring is checked for fraying, corrosion, or faulty connections.

- Steering and Suspension: Inspectors evaluate suspension components and steering mechanisms for integrity, as faults can lead to handling issues, especially with heavy loads.

- Driver Documentation: A valid CDL, current medical examiner’s certificate, and accurate hours-of-service records are required. Incomplete documentation can lead to penalties or driver disqualification.

Benefits of Regular DOT Inspections

Implementing systematic DOT inspections results in far-reaching benefits across all aspects of commercial fleet management:

- Enhanced Safety: Early detection of wear and potential hazards reduces accident risks, protecting drivers, cargo, and the public.

- Regulatory Compliance: Keeping up with inspections helps avoid audits and reduces the chances of spot checks or citations.

- Operational Efficiency: Regular inspections and timely maintenance lead to fewer breakdowns, reliable delivery schedules, and improved customer satisfaction and profitability.

Regular inspections aren’t simply a legal formality for fleet operators—they’re a strategic tool for building reliability, minimizing costly downtime, and maintaining a competitive edge in a crowded marketplace.